The Hydrochrome process itself is surprisingly straightforward but we definitely recomend that you have a bit of practice before using it so you can get a greater understanding how the system works before you start your project, again always start with very small items like like phone casees, them move up to the larger items once you are confident i using it.

Firstly a coat of sensitizer is applied, to prepare the surface for the application of the spray on chrome containing the silver nitrate, to ensure the chrome paint becomes chemically bonded to the surface. Water is rinsed over the item to make it ready for the silvering solutions to be applied. The silvering chrome solutions use real silver nitrate and not harmful traditional chroming chemicals to achieve the desired effect. The spray on chrome is rinsed again with distilled water before the application of an anti-oxidant. Compressed air is then used to dry the product. Once the item is dry, apply our specially formulated tinted chrome effect lacquer to prevent the yellowing,For outside use finish with 3-4 layers of our 2K UV guard lacquer, we have been running independant test on our spray o n chrome and have noticed a slight change in colour after 11 months outside.

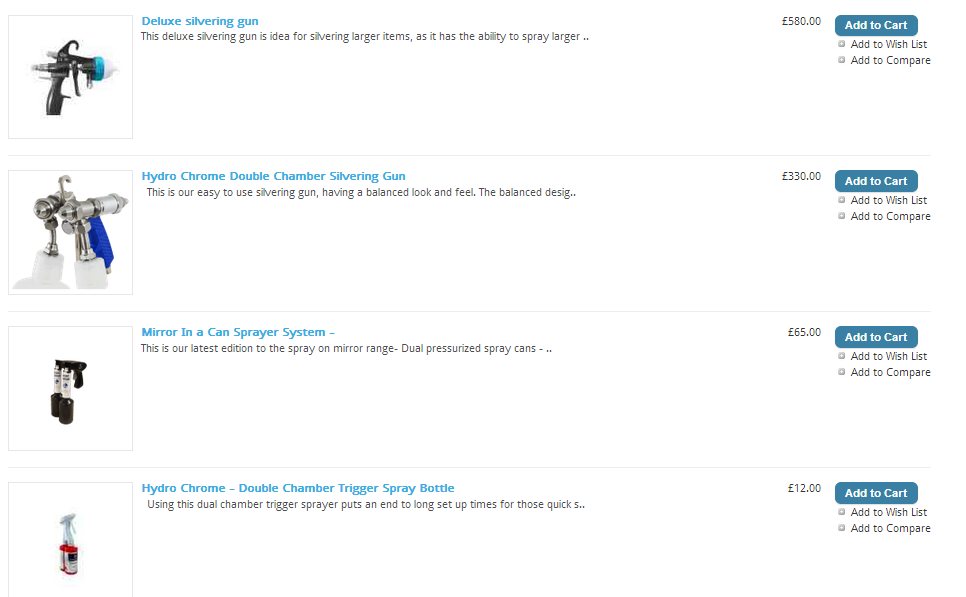

Although there are now many leading competitors; SpectraChrome who offer a spray on chrome application pack, Chrome FX, who use expensive equipment to apply the same chrome chemicals, chrome solutions and silver nitrate to achieve the chrome effect, but with a far greater price tag, the new Fantachrome which uses the same water based chrome solution, creating chrome for plastic using the same chrome spray, however again for a high cost and, lastly Cosmic Chrome who provide the chrome effect to large vehicles and objects, needless to say, again going to set you back a fortune. Despite SpectraChrome, Chrome FX, Fantachrome and Cosmic Chrome all costing a comparably small fortune (or very large one!) all of these companies use the same chrome spray technology that we do to achieve their chrome effect. However we pride ourselves in providing high quality products but at a lower cost so that anyone can achieve a quality spray on chrome effect, whether you’re using our Chrome@Home kit or our double chambered commercial spray guns.

This is our new and improved spray on mirror system that passes all the durability tests, the video below shows the cross hatch tape test there are not many in Europe that pass this type of test.

The base coat application is straight forward 2k product (you do not need to torch the base coat), this can be oven baked for 1.5 hout at 65c, as soon as it has cooled down you can silver then apply the topcoat so the whole process is completed in 2-3 hours.

CONTACT US

Custom Creation Paints Room 120

Bedford Technology Park

Thurleigh, Bedfordshire

MK44 2YP, UK

Tel: 01480 477824

Email: sales@customcreationpaints.co.uk

Bedford Technology Park

Thurleigh, Bedfordshire

MK44 2YP, UK

Tel: 01480 477824

Email: sales@customcreationpaints.co.uk

No comments:

Post a Comment